Products Sectoin

Technical Specifications

| Test Item | Test Methods |

|---|---|

| Erichsen | Cross cutting by 5mm interval and then pushing by 6mm in depth with Erichsen tester |

| Impact | Drop 500g & 1/2 inch diameter steel ball(Dupont Type) from a height of 500mm |

| Bending | 180。 1T Bending at 20℃(CR, EGI, GI) |

| Pencil Hardness | Check the trace mark when draw a line with Mitsubishi UNI pencil @ 45O direction & 500g pressure |

| Salt spray(Flat surface) | Spray with 5% salt water with 35℃ |

| Salt spray(Cross cutting) | Cross cutting with razor blade till it slightly touches on substrate metal and then test as same as above |

| Resistance to Alkali | 20±5℃× 5% NaOH × 24 Hrs |

| Resistance to Acid | 20±5℃× 5% HCl × 24 Hrs |

| Boiling water | 98℃ water × 1Hrs and leave it for 1hr |

| Pollution resistance | Leave coffee, olive oil for 24Hrs, and then erase with methyl alcohol |

| Test Item | PET/PVC Laminated Steel |

PET Laminated Steel |

PVC Laminated Steel |

PVF Laminated Steel |

PP Laminated Steel |

Related Standard |

|---|---|---|---|---|---|---|

| Erichsen | No Peeling | No Peeling | No Peeling | No Peeling | No Peeling | KS B 0812 KS M 3343 |

| Impact | No Peeling &Crack |

No Peeling &Crack |

No Peeling &Crack |

No Peeling &Crack |

No Peeling &Crack |

KS D 3520 |

| Bending | No Peeling &Crack |

No Peeling &Crack |

No Peeling &Crack |

No Peeling &Crack |

No Peeling &Crack |

KS D 3520 KS M 3343 |

| Pencil Hardness |

Over B grade |

Over HB grade |

Over B grade |

Over HB grade |

Over HB grade |

KS D 3520 |

| Salt spray (Flat surface) |

No change of surface CR:240Hrs EGI:360Hrs GI:360Hrs |

No change of surface CR:240Hrs EGI:360Hrs GI:360Hrs |

No change of surface CR:240Hrs EGI:360Hrs GI:360Hrs |

No change of surface GI:1000Hrs Rust& decoloration |

No change of surface CR:240Hrs EGI:360Hrs GI:360Hrs |

KS D 9502 |

| Salt spray (Cross cutting) (1 Cycle=8Hrs Spary+ 16Hrs Pause) (10 Cycle => 240Hrs) |

Rust& decoloration spread within 4mm from the cross cutting Edge CR:90Hrs EGI:240Hrs GI:240Hrs |

Rust& decoloration spread within 4mm from the cross cutting Edge CR:90Hrs EGI:240Hrs GI:240Hrs |

Rust& decoloration spread within 4mm from the cross cutting Edge CR:90Hrs EGI:240Hrs GI:240Hrs |

spread within 4mm from the cross cutting Edge GI:360Hrs |

Rust& decoloration spread within 4mm from the cross cutting Edge CR:90Hrs EGI:240Hrs GI:240Hrs |

KS D 9502 |

| Resistance to Alkali |

No change of Color&surface |

No change of Color&surface |

No change of Color&surface |

No change of Color&surface |

No change of Color&surface |

JS M 3343 JIS K 6744 |

| Resistance to Acid |

No change of Color&surface |

No change of Color&surface |

No change of Color&surface |

No change of Color&surface |

No change of Color&surface |

JS M 3343 JIS K 6744 |

| Boilling water |

No Peeling, Crack&Blister |

No Peeling, Crack&Blister |

No Peeling, Crack&Blister |

No Peeling, Crack&Blister |

No Peeling, Crack&Blister |

KS M 3343 JIS K 6744 |

| Pollution resistance |

No change of surface |

No change of surface |

No change of surface |

No change of surface |

No change of surface |

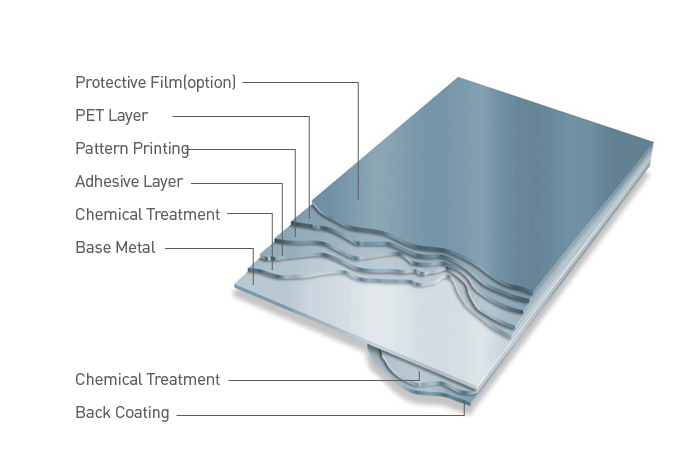

Producing Ability

| Item / Std. | POSCO | KS | JIS | ASTM |

|---|---|---|---|---|

| CR | CSP1 | SCP1(KSD3512) | SPCC(JISG3141) | A366 |

| EGI | EGS1 | SECC(KSD3528) | SECC(JISG3313) | A591-CQ |

| GI | CGCC | SGCC(KSD3506) | SGCC(JISG3302) | A526 |

| VCM | Thickness | Width | Length |

|---|---|---|---|

| 0.4 ~ 1.2 | 400 ~ 1350 | 300 ~ 5000 |

| Standard | Yield Point(Kg/mm2) | Tensile strength(Kg/mm2) | Elongation Ratio(%) |

|---|---|---|---|

| Less than 36 | Over 28 | Over 30 |

| Tolerance | Width | Length | Diagonal Tolerance |

|---|---|---|---|

| ±0.5 | ±0.5 | Less then 1mm |