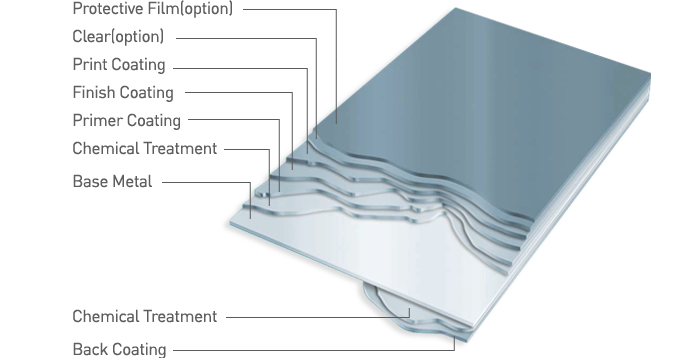

제품단면

기술사양

| Test Item | Test Methods |

|---|---|

| Gloss | 60˚ gloss meter |

| Pencil hardness test | Scratched Mitsubishi uni-pencil harden than “H” |

| Cross cut erichsen test | 100 grids of 1mm X 1mm by knife and pushed up by 6mm with Erichsen tester |

| Cross cut test | Leave 1 hour after boiling test, 100 grids of 1mm X 1mm by knife |

| Impact test | Drop steel ball of 1000gr weight and 12.7mm diameter at 50cm height |

| Bending test | Completely folded, wrapping Mendril bar of diameter equivalent to 2 layers of test sample |

| Salt water spray test | Sprayed with 5% salt water at 35 °c |

| Weathering test | Over 1000 hours with Weather-O-Meter |

| Resistance to Acid test | Spot 5% HCI(of H2SO4) and leave 24 hours |

| Resistance to Alkali test | Spot 5% NaOH and leave 24 hours |

| Resistance to Solvent test | Rubbed by gauze soaked in M.E.K(of zylene) until the base metal exposed |

| Resistance to boiling test | Dipped in boiled water for 1 hour |

| Ultraviolet rays test | Exposed at 100V/10W ultraviolet rays lamp from 150mm distance for 6 hours |

| Test Item | RMP | HDP | HPP | Related Spec. | |

|---|---|---|---|---|---|

| Gloss | 5%-110% | 5%-110% | 5%-110% | 80%-110% | option |

| Pencil hardness test | H Good | 2H Good | F~H Good | H Good | KS D 3520 |

| Cross cut erichsen test | Good | Good | Good | Good | KS B 0812c / KS M 3343 |

| Cross cut test | Good | Good | Good | Good | |

| Impact test | No crack | No crack | No crack | No crack | KS D 3520 |

| Bending test | 5T No crack 이하 | 5T No crack 이하 | 0-1T No crack | 0-2T No crack | KS D 3520 / KS M 3343 |

| Salt water spray test | 500Hrs | 500Hrs | 500Hrs | 500Hrs | KS D 9502 / ASTM B 117 |

| Weathering test | cc | 1000Hrs Good | 500Hrs Good | 1000Hrs Good | JIS Z 0230 |

| Resistance to Acid test | 24Hrs Good | 24Hrs Good | 24Hrs Good | 24Hrs Good | KS M 3343 / PCTM 61310 |

| Resistance to Alkali test | 24Hrs Good | 24Hrs Good | 24Hrs Good | 24Hrs Good | KS M 3343 / PCTM 61310 |

| Resistance to Solvent test | 50times Good | 50times Good | 100times Good | 50times Good | |

| Resistance to boiling test | No change | No change | |||

| Ultraviolet rays test | No change | No change |

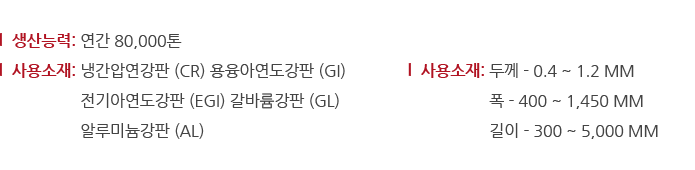

생산능력

| Item / Std. | POSCO | KS | JIS | ASTM |

|---|---|---|---|---|

| CR | CSP1 | SCP1(KSD3512) | SPCC(JISG3141) | A366 |

| EGI | EGS1 | SECC(KSD3528) | SECC(JISG3313) | A591-CQ |

| GI | CGCC | SGCC(KSD3506) | SGCC(JISG3302) | A526 |

| PCM | Thickness | Width | Length |

|---|---|---|---|

| 0.3 ~ 1.2 | 500 ~ 1500 | 350 ~ 50000 |

| Standard | Yield Point(Kg/mm2) | Tensile strength(Kg/mm2) | Elongation Ratio(%) |

|---|---|---|---|

| Less than 36 | Over 28 | Over 30 |

| Tolerance | Width | Length | Diagonal Tolerance |

|---|---|---|---|

| ±0.5 | ±0.5 | 1mm 이내 관리 |